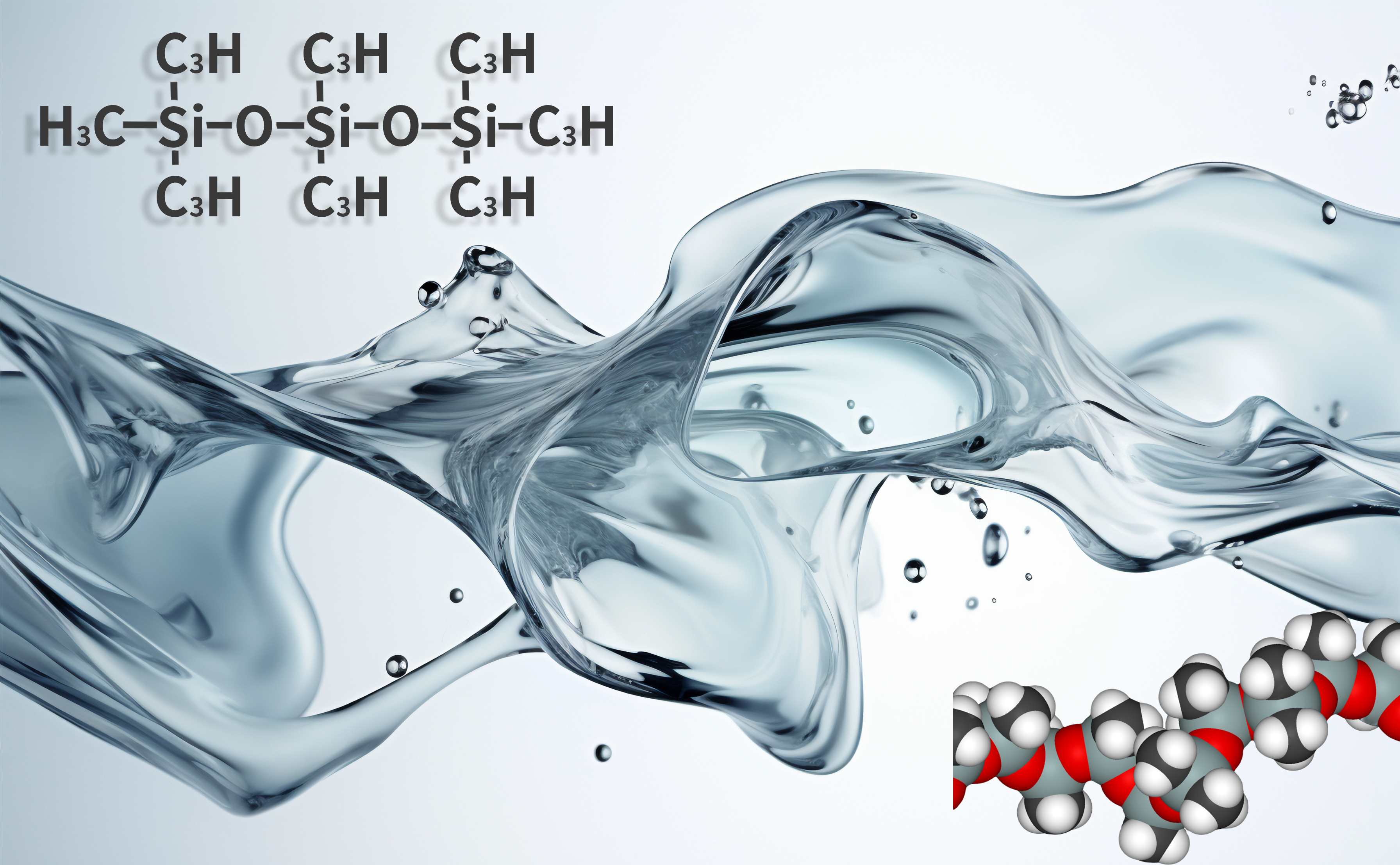

Application of polydimethylsiloxane (PDMS)

Polydimethylsiloxane (PDMS) is an important siloxane polymer, belonging to high molecular weight organosilicon compounds, commonly known as silicone. It is optically transparent and is generally considered to be inert, non-toxic and non-flammable. Due to its unique physical and chemical properties, PDMS has been widely used in many fields.

PDMS is commonly used in advanced lubricants, anti-vibration oils, insulating oils, defoamers, mold release agents, polishes and vacuum diffusion pump oils. Among various silicone oils, methyl silicone oil is the most widely used and is the most important variety of silicone oil, followed by methylphenyl silicone oil. In addition, there are ethyl silicone oil, nitrile-containing silicone oil, etc. Various functional silicone oils and modified silicone oils are mainly used for special purposes.

1. Medical field

PDMS is increasingly used in the medical field, mainly for the manufacture of biocompatible materials. For example, it is used to make medical devices, catheters and implants. In addition, PDMS is also widely used in microfluidic devices and biochips for biological analysis and drug screening.

2. Cosmetics and personal care products

2.1. Lubricating properties: Polydimethylsiloxane has excellent lubricating properties. After being applied to the skin, it can form a uniform waterproof protective film, which is non-sticky and greasy, and has good gloss.

2.2. Anti-ultraviolet: PDMS will not oxidize and deteriorate under ultraviolet rays, avoiding irritation to the skin.

2.3. Antistatic: Studies have shown that after using skin creams containing polysiloxane, skin static electricity can be completely eliminated, and it has a significant dust-proof effect.

2.4. Slow-release of flavors: PDMS has a slow-release and fragrance-fixing effect on flavors and fragrances, with a long fragrance retention period and high stability.

2.5. Safety: PDMS is non-toxic, odorless, tasteless, non-irritating and non-allergic to the skin, highly safe, and has a certain effect on certain skin diseases, such as eczema and neurodermatitis.

3. Leather products

Polydimethylsiloxane can be used for fibers and leathers: water repellent, softener, feel improver, defoamer in dyeing industry, lubricant for sewing thread. This emulsion can be used for leather fatliquoring to enhance the hydrophobicity, softness and comfort of leather. Treating the leather surface with it can enhance the wear resistance, water resistance and demoulding properties.

4. Brightener

Polydimethylsiloxane is suitable for use as a brightener component for automobiles, furniture, shoes, cement products, etc., including automobile brighteners, foam furniture cleaners, vinyl roof cleaners, and building material brightener formulas. The minimum amount can achieve the best effect.

5. Release agent

PDMS can be used as a release agent for rubber or plastic products, suitable for brake pads, screw heads, plugs, etc. When used, it can be directly or diluted 10-200 times with low hardness water. It has the characteristics of high efficiency and stability.

6. Lubricant

PDMS can be used as a lubricant for extruded rubber products, suitable for textile processes such as weaving yarn, suture lubrication, socks and underwear production.

Other fields

Polydimethylsiloxane is a food-grade defoamer that can be used for defoaming in the brewing and fermentation processes of medicines and foods. Due to its non-toxicity, PDMS is also used as a medical defoamer to treat acute pulmonary edema and flatulence. Silicones mentioned in pharmaceutical monographs are a general term for a class of organic silicon oxide polymers, and dimethyl silicone oil is a commonly used one. In addition, there are ethyl silicone oil, methylphenyl silicone oil, etc.

In tablets, polishes and insect wax, a small amount of PDMS is often added to enhance brightness and moisture resistance. In ointments, due to its good lubricity, PDMS is easy to apply and does not stain clothes, does not hinder the normal function of the skin, and becomes an ideal hydrophobic matrix.

Conclusion

Polydimethylsiloxane has become an indispensable material in many industries due to its unique properties and versatility. With the advancement of science and technology, the application field of PDMS will continue to expand, providing support for more innovations.