Brief Introduction of Silicone Softener

Softeners can be adsorbed on the fiber surface of textiles to make them smooth, thereby improving the feel and comfort of the product. Among various textile auxiliaries, the type and dosage of softeners rank first. Among them, silicone softeners are widely used in textile, plastics, rubber and other industries due to their excellent performance and remarkable effects. This type of softener is mainly an emulsion or microemulsion of polysiloxane and its derivatives. In addition to improving the softness and feel of the material, it can also provide excellent heat resistance, water resistance and UV resistance. In addition, this type of softener The material is non-toxic, does not pollute the environment, and the cost is not high, so it is welcomed by various industries.

1. Classification of silicone softeners

According to the chemical reactivity and fiber reactivity of its active ingredient polysiloxane silicone emulsion, it can be divided into three categories: inactive, active and reactive group modification.

1.1 Inactive silicone softener

This type of softener is mainly dimethyl silicone oil, called polydimethylsiloxane (DMPS), or methyl silicone oil for short. It can give fabrics better softness and heat resistance. Its emulsion products include Dow Corning 36, 37, etc. Due to its low degree of polymerization, it cannot cross-link itself and does not react to fibers. The feel, fastness and elasticity of the finished fabric are not ideal. Therefore, it cannot be used directly as a softener. It must be prepared into a silicone oil emulsion under the action of an emulsifier before it can be applied to fabrics to increase wash resistance, such as Japan's DIC Silicon softener 500 and Bayer's Perlie SI. This type of softener is called the first generation of silicone softeners.

1.2 Active silicone softener

This type of softener mainly replaces the two ends of the linear structure of dimethyl polysiloxane (DMPS) with hydroxyl groups (-OH), or caps it with hydroxyl groups to make it have a certain hydrophilicity. The emulsion made of this end-hydroxyl-capped dimethyl polysiloxane is the so-called silicone hydroxy emulsion. There are quite a lot of such products. They can be used as softeners alone or cross-linked with other silicones to form a water-insoluble molecular film on the fiber. Therefore, the finished fabric has a certain waterproof and wash-resistant effect. Products include Dow Corning 1111, Ultratex FSA of Ciba Geigy of Switzerland, etc. This type of softener is the second generation of silicone softeners. According to the surfactants used in the preparation, it can be divided into cationic, anionic, nonionic and composite ionic types. It can be selected according to the type of fabric.

1.3 Modified silicone softener

This type of softener introduces other active groups into the silicone molecular chain to make it have special functions to meet the needs of high-end finishing of various fabrics, improve the antistatic, anti-oil and hydrophilic properties of the fabric, and make the chemical fiber fabric have many advantages of natural fabrics, becoming a third generation of silicone softening finishing agent with special functions.

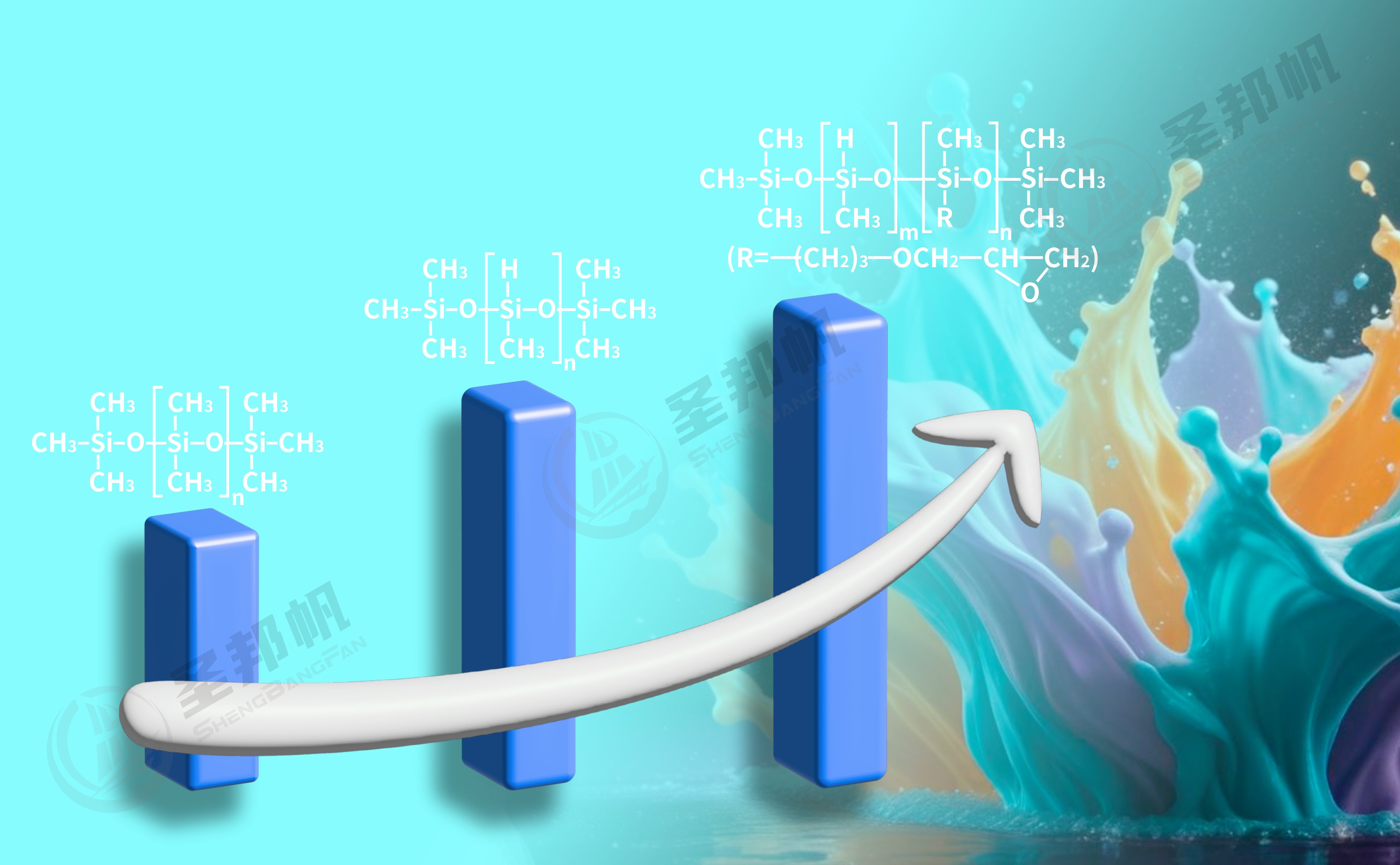

2. Development of modified softeners

Since the advent of modified silicone softeners, they have been widely used in fabric finishing, and research and development of such products at home and abroad are still ongoing. This type of softener significantly improves the hydrophilicity, washability and shrinkage resistance of the fabric by introducing various active groups such as amino, epoxy, polyether, and hydroxyl groups into the side chain of siloxane, while giving the fabric a unique style based on the characteristics of different groups.

At present, new product research and development worldwide is mainly divided into three categories: the first type is reactive type, including amino, epoxy, carboxyl, methacryl and fluoroalkyl modifications; the second type is non-reactive type , mainly based on polyether modification; the third type is mixed type, such as the combination of polyether amino group and epoxy group. In practical applications of textiles, polyether modification is the most common, and amino-modified softeners are also commonly used. Most products adopt mixed modification, including modification of a small amount of single amino, epoxy, carboxyl and fluoroalkyl reactive groups.

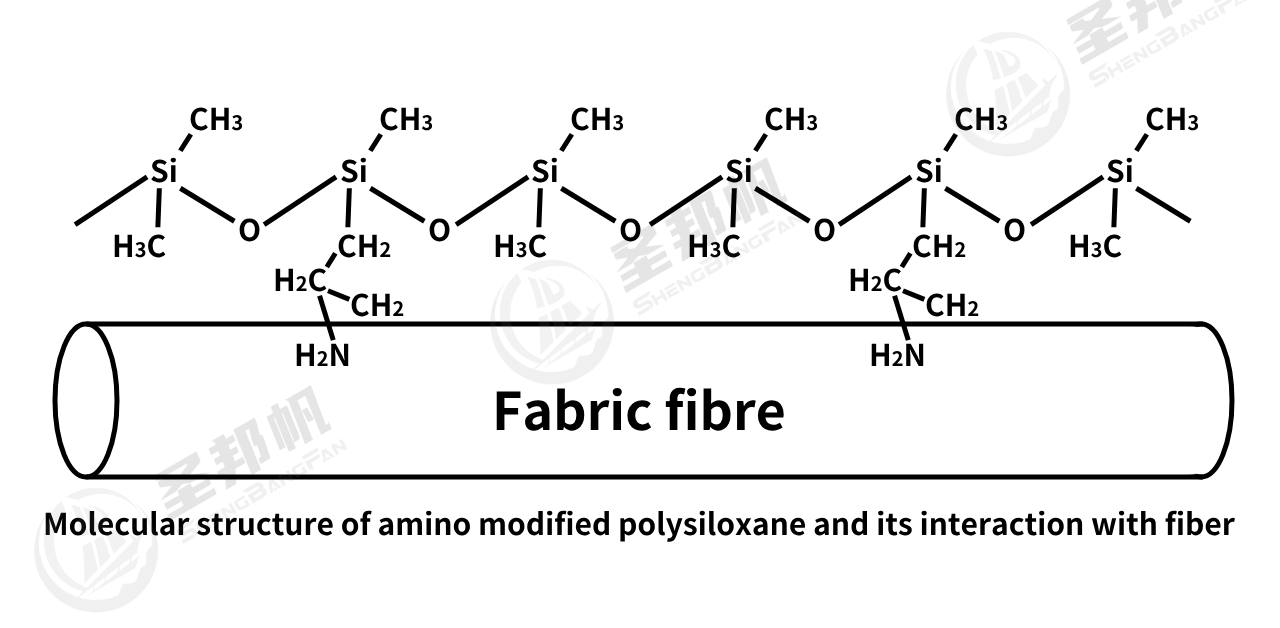

2.1 Amino-modified silicone softener

Amino-modified silicone softeners refer to polysiloxanes with amino groups on their side chains or end groups. These amino groups can be primary ammonia, secondary ammonia, tertiary ammonia or ammonium salts, or they can be aromatic ammonia. Its synthesis methods mainly include bulk polymerization and emulsion polymerization. The elasticity of fabrics treated with amino-modified silicone softeners is significantly improved, the combination with fibers is very strong, the washing resistance is good, and the hand feels soft, smooth and elastic. At the same time, this softener also significantly improves the mechanical properties of the fabric and has certain anti-wrinkle and anti-shrink effects. Among amino-modified silicones, products containing aminoethyl and aminopropyl groups are particularly effective.

However, amino-modified silicone softeners are prone to yellowing under heat or ultraviolet irradiation, so they are not suitable for softening finishing of light-colored fabrics. At present, this type of softener is still being improved. Improvement methods include epoxidation, amidation or secondary amination, etc., controlling the degree of modification or using mixed modification, and can also be prepared into stable silicone microemulsions.

2.2 Epoxy modified silicone softener

According to the reaction type, there are three main synthesis methods for epoxy-modified silicone: the first is a hydrosilation addition reaction between hydrogenated silicone oil and terminal alkenyl epoxy compounds; the second is a polymerization reaction of octamethylcyclotetrakis Silicone (D4) or epoxy-substituted cyclotetrasiloxane (D4) is combined; the third is other synthesis methods, such as the condensation reaction of α,ω-dihydroxy silicone oil and epichlorohydrin. Epoxy groups are highly reactive and can undergo cross-linking reactions with hydroxyl, amino and carboxyl groups on the surface of the fiber to form solid chemical bonds, thereby giving the treated fabric a lasting finishing effect. Epoxy-modified fabrics usually do not turn yellow and have good stability and softness, but have poor slipperiness and water absorption. In order to improve water absorption, a strong water-absorbing group can be grafted on the end of the epoxy group.

2.3 Polyether modified silicone softener

The preparation of polyether-modified silicone softeners can use a variety of reaction mechanisms, such as hydrosilylation reaction, esterification reaction, Michael addition reaction, active hydrogen epoxy addition reaction, alcohol hydrogen condensation and siloxane hydrolysis condensation wait. At present, these preparation technologies have become mature. Polyether-modified silicone has good adaptability, biocompatibility and low glass transition temperature, so it has advantages in performance that other surfactants cannot match. After introducing water-soluble unsaturated polyether into the side chain of polysiloxane, hydrophobic silicone can be converted into hydrophilic silicone. Polyether-modified fabrics also exhibit good antifouling and antistatic properties, but are relatively weak in softness and washability. Due to its good compatibility with other finishing agents, polyether-modified silicone can be used in the same bath as dyes. In addition, polyether-epoxy mixed modified silicone combines the advantages of polyether and epoxy silicone, making up for their respective shortcomings. It is a multi-functional multi-component silicone finishing agent with excellent performance.

Modified organic silicon soft agent also has a carboxyl, cymbal, alcohol, and ester -based modification. The carboxyl -based silicon reacts with unsaturated fatty acids through platinum catalysts. It has good chemical response and polarity, which can improve the combination of natural fibers and anti -static resistance of chemical fiber. The cymbal modified organic silicon is prepared by sulfur sulfur or acetic acid method, which gives the wool resistance and lubrication. Alcohol -alcohol -modified silicon reacts with silicone oil through unsaturated alcohol, which improves the chromosome and water resistance of the fabric. The ester -altering organic silicon is legally synthesized by the emulsion polymerization, making the fabric feel soft and elastic. Different types of modified organic silicon soft agents can effectively meet the organizational needs of various fabrics.

Summarize

Silicone softeners have become indispensable and important additives in the modern textile industry due to their excellent performance and wide application prospects. With the advancement of science and technology and the continuous emergence of new materials, the application fields of silicone softeners will be further expanded and promote the development of related industries. In the future, the development of more environmentally friendly and efficient silicone softeners will be an important trend in the industry.