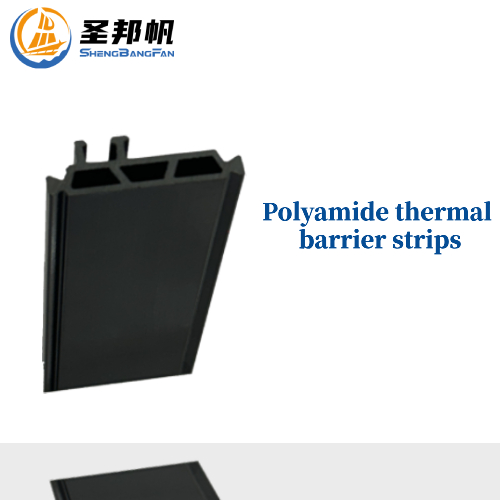

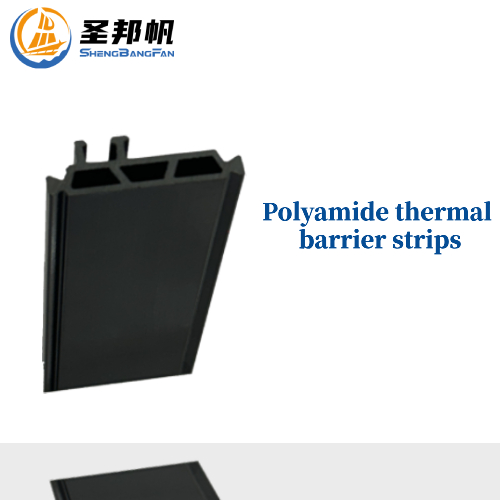

Polyamide thermal barrier strips

Dear Visitor/Customer,

Hello!

Polyamide insulation strips are made of polyamide 66 (PA66) with a main component of no less than 65%, alkali-free glass fiber and various additives. Compared with aluminum alloy materials, the overall performance is better, and the thermal conductivity is only 1 of aluminum alloy. -2%, which can effectively reduce energy conduction loss inside and outside aluminum alloy doors and windows. Widely used in construction, automobile, high-speed rail, furniture, home appliances and other industries.

ANNEX:

Introduction to Polyamide thermal barrier strips

Main ingredients : Polyamide 66

Full name : Polyamide thermal barrier strips for building aluminum-alloy profiles

Based on PRC National Standard: GB/T 23615.1-2017

Appearance : Long black solid

Polyamide thermal barrier strips are mainly used in broken bridge aluminum alloy doors and windows, and are the terminal products extending the current Shengbangfan polyamide product industry chain. At present, Shengbangfan has more than 60 most advanced insulation strip production lines with fully automatic detection devices, with an annual production capacity of 150 million meters. The cross-section size and shape of the heat insulation strip can be customized according to customer requirements, the production process strictly follows internal control standards, and professional quality management and testing personnel control everything from raw material purchase, production samples, production process flow, product inspection, packaging and coding, and finished product shipment to ensure that the products quality.

We provide Customisation and Free Sample of dimethyl polyamide thermal barrier strips.

If you have questions, please submit a bill at the bottom of this page or contact us.

Related data of type I polyamide material:

Technical parameters

NO | Item | Performance requirement | SBF Testc data | |

1 | Density | (1.30±0.05)g/c m2 | (1.30±0.05)g/c m2 | |

2 | DSC Melting point | ≧255℃ | 258℃ | |

3 | Testing for tensile cracks | NO crack | NO crack | |

4 | Shore hardness | 80±5 | 83 | |

5 | Impact strength (unnotched) (23℃±2℃) | ≧50KJ/m2 | 65KJ/m2 | |

6 | Tensile strength (vertical) (23℃±2℃) | ≧90MPa | 95MPa | |

7 | Elongation at break (vertical) (23℃±2℃) | ≧3% | 3.2% | |

8 | Elasticity modulus (vertical) (23℃±2℃) | ≧4500MPa | 4980MPa | |

9 | Shape I (section depth、20mm) | ≧90MPa | 103MPa | |

Shape I (section depth≧20mm) | ≧80MPa | 91MPa | ||

Specia l Shape | ≧25MPa | 28MPa | ||

10 | Shape I (section depth、20mm) | ≧55MPa | 58MPa | |

Shape I (section depth≧20mm) | ≧45MPa | 52MPa | ||

Special Shape | ≧20MPa | 26MPa | ||

Space is limited, please contact us for more detailed parameters! When selecting non-type I polyamide profiles, engineering design calculations should be carried out. | ||||