Properties and uses of dimethyl silicone oil

1.What is dimethylsilicone oil

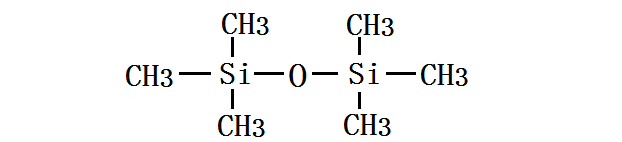

Dimethyl silicone oil is an organic silicon compound primarily composed of dimethylsiloxane. It typically appears as a colorless, odorless, and transparent liquid, exhibiting excellent chemical and thermal stability. The structure consists of a Si—O—Si main chain, with silicon atoms connected to methyl groups in a linear arrangement. Due to the weak intermolecular forces, the molecules adopt a helical structure with methyl groups oriented outward, allowing for free rotation. The structural formula is as follows:

This unique structure imparts a series of characteristics, including colorless transparency, a wide viscosity range (from 0.65 to 1,000,000 mm²/s), a low temperature-viscosity coefficient, a high thermal expansion coefficient, low vapor pressure, high flash point, resistance to extreme temperatures, weathering, radiation, low surface tension, high compressibility, resistance to oxidative plasma, excellent electrical insulation, shear resistance, film-forming capability, hydrophobicity, defoaming properties, release agent characteristics, high gloss, and inertness toward materials. Additionally, it is chemically inert, non-corrosive, and physiologically inert, which collectively contribute to its broad range of applications.

In the market, dimethyl silicone oil is typically classified into three categories based on viscosity: low viscosity silicone oil (0.65 to 50 mm²/s), medium viscosity silicone oil (50 to 1,000 mm²/s), and high viscosity silicone oil (5,000 to 1,000,000 mm²/s).

2. Properties

Chemical Stability: Dimethyl silicone oil exhibits excellent chemical resistance, capable of withstanding various acids, bases, and salts.

Thermal Stability: It remains stable at high temperatures and is not prone to decomposition, making it suitable for a wide temperature range.

Low-Temperature Fluidity: Dimethyl silicone oil maintains good fluidity in low-temperature conditions, making it ideal for cold applications.

Lubricating Properties: It demonstrates exceptional lubricating characteristics, effectively reducing friction and wear.

Electrical Insulation: As a superior electrical insulating material, dimethyl silicone oil is suitable for insulation and protection of electronic products.

Surface Activity: Dimethyl silicone oil possesses good wettability and surface activity, enhancing the surface properties of materials.

3. Applications

3.1 Textile Additives: Dimethyl silicone oil is widely used in oil agents for fiber raw silk and cotton, spinning oil agents, and as a smoothing agent for sewing threads. The oil agents for raw silk and cotton are typically low-viscosity dimethyl silicone oils, while the smoothing agents for sewing threads are medium to high-viscosity. Due to its excellent thermal stability and low viscosity-temperature coefficient, dimethyl silicone oil is used as a spinning oil agent, primarily in the spinning processes of nylon and polyester, to prevent filament breakage and looseness.

3.2 Defoaming Agents: With its low surface tension, insolubility in water, vegetable and animal oils, and high-boiling mineral oils, along with good chemical stability and non-toxicity, dimethyl silicone oil serves as an ideal raw material for defoaming agents. By mixing it with fumed silica to create a silicone paste, which is then emulsified into a water-based silicone emulsion defoamer, it finds extensive application across industries such as petroleum, chemicals, healthcare, pharmaceuticals, food processing, textiles, dyeing, and papermaking. Adding just 10-100 PPM can effectively reduce foam.

3.3 Release Agents: Dimethyl silicone oil is characterized by its non-stick properties with rubber, plastics, and metals, as well as its film-forming ability, making it widely used in the manufacturing of release agents for various rubber and plastic products.

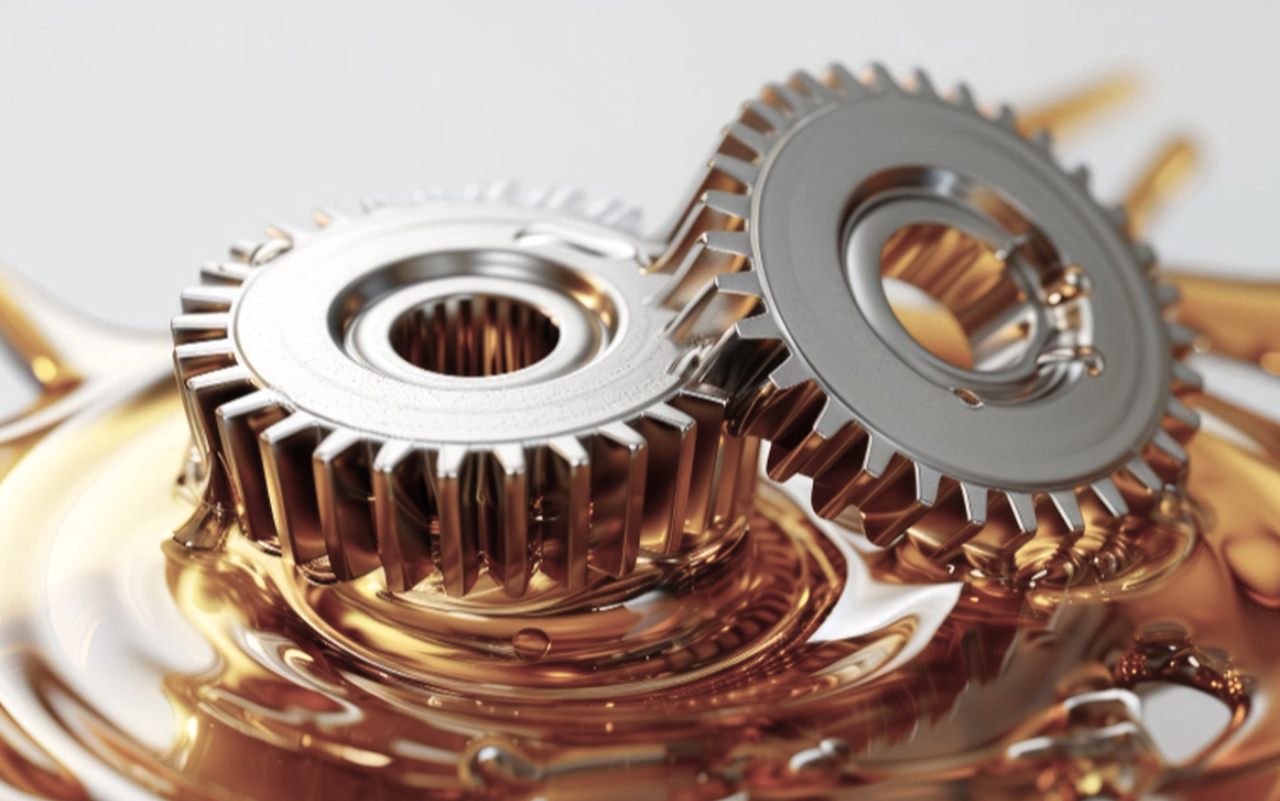

3.4 Lubricants: It is used as a lubricant for rubber and plastic bearings and gears. Lubricants made from dimethyl silicone oil are typically used in grease form.

3.5 Other Applications: Thanks to its high flash point, odorlessness, colorlessness, transparency, and non-toxicity to humans, dimethyl silicone oil is used as a heat transfer medium in oil baths or thermostats in industries and research involving steel, glass, and ceramics. Its excellent shear resistance also makes it suitable as hydraulic oil, particularly for aviation hydraulic systems. Additionally, when used to treat artificial silk spinning heads, it effectively eliminates static electricity and improves filament quality.

Conclusion

In summary, dimethyl silicone oil is a versatile and valuable organic silicon compound with a wide array of properties that make it suitable for various industrial applications. Its unique molecular structure grants it exceptional chemical and thermal stability, low surface tension, and excellent lubricating and insulating characteristics. From textile additives and defoaming agents to release agents and lubricants, dimethyl silicone oil plays a crucial role in enhancing product performance across multiple sectors. Its non-toxic and inert nature further expands its usability, making it an essential material in industries such as healthcare, food processing, and manufacturing. As technology advances and new applications emerge, the significance of dimethyl silicone oil is likely to grow, solidifying its position as a key component in modern industrial processes.