Understand PA66 in one article

What is PA66?

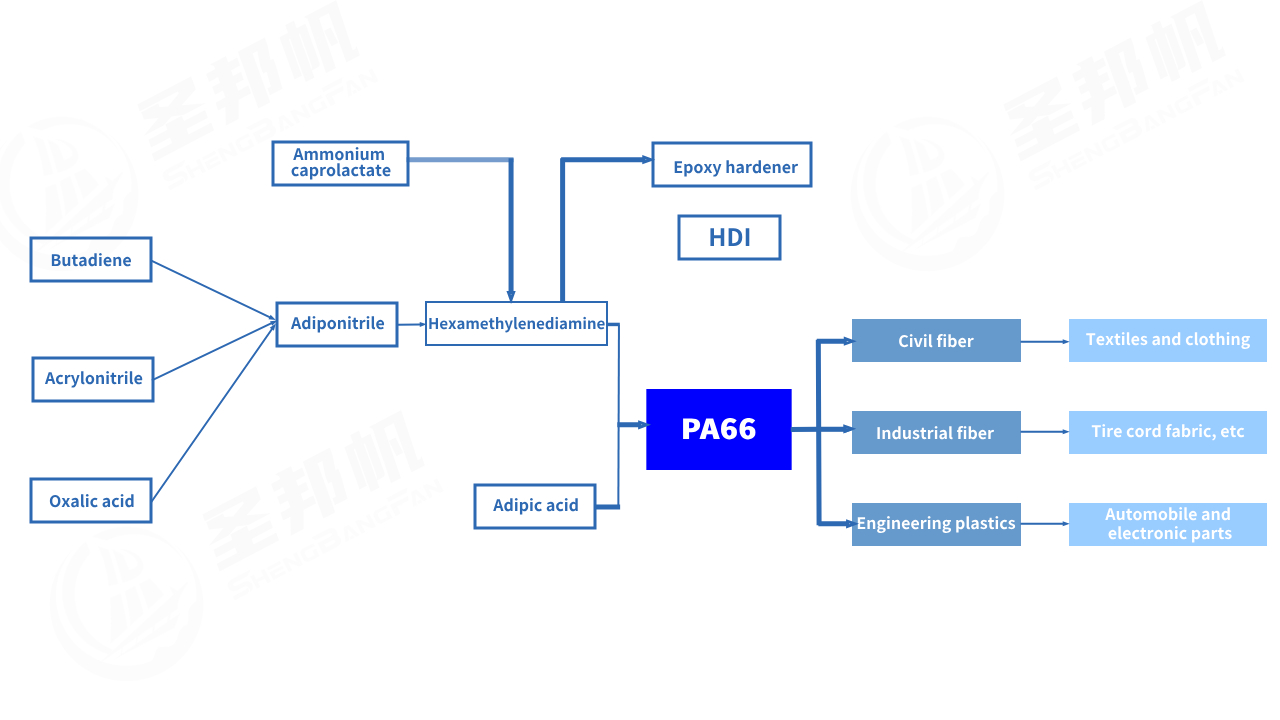

PA66 (polyamide 66 or nylon 66) is a translucent or opaque light yellow crystalline polymer with strong plasticity. It is an important engineering plastic. It is made by polycondensation of adipic acid and hexamethylenediamine, and its molecular formula is [-NH-(CH2)6-NH-CO-(CH2)4-CO-]n. PA66 is mainly used in engineering plastics, industrial fibers, and civilian fibers, such as gears and lubricating bearings, replacing non-ferrous metal materials for machine housings, automobile engine blades, clothing, etc.

Brief introduction to the development of PA66

Polyamide 66 (nylon 66) is the earliest industrially produced polyamide variety. DuPont of the United States first published a patent in 1937. A pilot plant was established in 1938, and industrial production began in 1939. It was widely used in the military field during World War II, and developed into an important material for the production of fibers, films and plastics after the war. Since then, polyamide 6, 610, 11, 1010, copolyamide and other varieties have been developed one after another. In 1966, Germany began to mass produce polyamide 12, and in 1972, DuPont in the United States achieved industrial production of aromatic polyamide. Since the 1970s, the modification and raw material route of polyamide have turned to petrochemicals, making it a type of polymer material with many varieties and wide applications.

PA66 Production Process

The starting raw materials for the production of polyamide mainly come from petroleum, and a small amount comes from coal and plant raw materials. Nylon 66 is also known as polyhexamethylene adipamide. Its monomers adipic acid, hexamethylenediamine and caprolactam of polyamide 6 are mainly derived from cyclohexane obtained by hydrogenation of benzene, and a small part comes from phenol. One monomer of nylon 610 and nylon 1010 is sebacic acid, and the monomer aminoundecanoic acid of nylon 11 is obtained by alkaline hydrolysis of castor oil, an agricultural and forestry chemical product. The monomer butadiene of nylon 12 is the product of separation of carbon four fractions. All monomers are refined before polymerization to meet the polymerization grade requirements.

Related applications of PA66

Polyamide plastic products are widely used as various mechanical and electrical parts, including bearings, gears, pulley pump impellers, blades, high-pressure seals, gaskets, valve seats, bushings, oil pipelines, oil reservoirs, ropes, transmission belts, grinding wheel adhesives, battery boxes, electrical coils, cable connectors, etc. There are also large production of packaging tapes and food films (high-temperature films for cooked food and low-temperature films for refreshing beverages). The polyamide plastics developed by Monsanto Company of the United States for reaction injection molding, also known as RIM nylon, have attracted much attention from various countries. Some countries have made glass-reinforced RIM nylon large automobile shells, which has enabled polyamide to find another way to reduce weight, save energy and reduce costs in the competition with metal materials in the automotive manufacturing industry.

The main varieties of polyamide fibers (aliphatic) are nylon 66 and nylon 6, the latter also known as nylon. They have high strength, good resilience, the highest wear resistance among textile fibers, and resistance to multiple deformations and fatigue resistance are close to polyester, higher than other fibers. They have good heat absorption, but poor light and heat resistance. Polyamide fiber filaments can be made into socks, underwear, shirts, sports shirts, ski jackets, raincoats, etc.; short fibers can be blended with cotton, wool and viscose fibers to give the fabric good wear resistance and strength. It can also be used as nylon fasteners, carpets, decorative fabrics, etc. It is mainly used in the industry to make cord fabrics, conveyor belts, fishing nets, cables, etc.

PA66 is a leader in the engineering plastics industry, and its development in civil fibers and industrial fibers is getting better and better. With the continuous advancement of technology, PA66 will surely play a more important role in future industrial manufacturing. As a factory specializing in the production of PA66 particles, we have advanced production equipment and a strict quality management system to ensure that we provide customers with high-quality and stable products. Our PA66 particles have excellent mechanical properties, high temperature resistance, chemical corrosion resistance and other characteristics, and are widely used in many fields such as automobiles, electronic appliances, and machinery manufacturing. With excellent product quality and thoughtful customer service, we have become a well-known brand in the industry. We look forward to establishing a long-term and stable cooperative relationship with you and creating a better future together!

Please feel free to consult us at any time. We will do our best to provide you with satisfactory services. Let us work together to create brilliance!