Nylon: Revolutionizing Materials and Sustainability

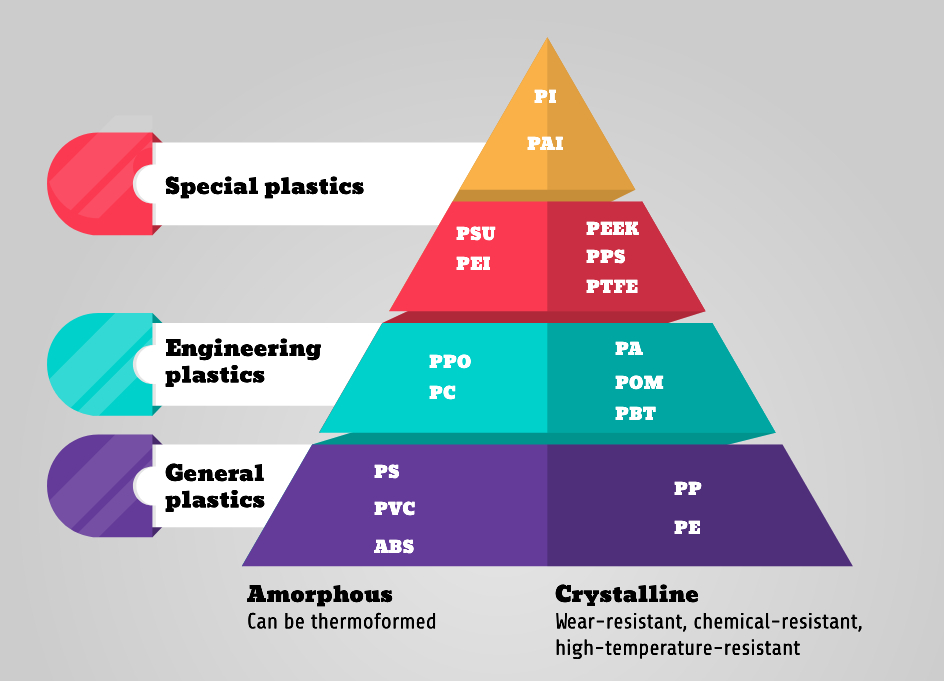

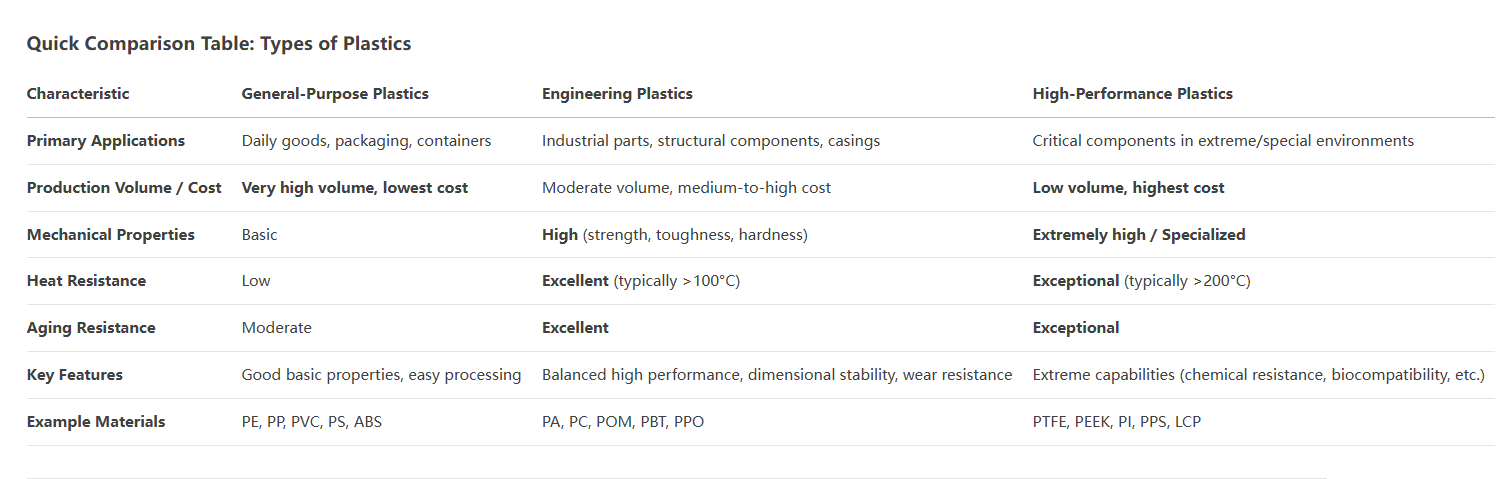

Plastic is a type of high-molecular-weight polymer. Depending on its usage characteristics, it is classified into three main types: General-Purpose Plastics, Engineering Plastics, and High-Performance Plastics.

Engineering Plastics is a general term for plastics used in industrial components or product casings. They generally possess higher strength, toughness, and hardness, along with excellent heat resistance and aging resistance.

Nylon, chemically known as polyamide (PA), is one of the five major engineering plastics and an extremely important synthetic polymer. The main chain of nylon molecules is rich in highly polar amide groups (-NHCO-), which give it extremely strong intermolecular forces; at the same time, it is easy to form a strong hydrogen bond network between the N-H and C=O groups in the amide groups. These structural characteristics jointly lay the foundation for the excellent comprehensive performance of nylon, making it outstanding in mechanical properties, heat resistance, machining properties, electrical properties, solvent resistance and flame retardancy.

In addition, nylon also has significant advantages such as a wide range of raw material sources, diverse varieties, high cost-effectiveness, easy recycling, and excellent dyeing properties. Its products have the characteristics of high precision and good dimensional stability.

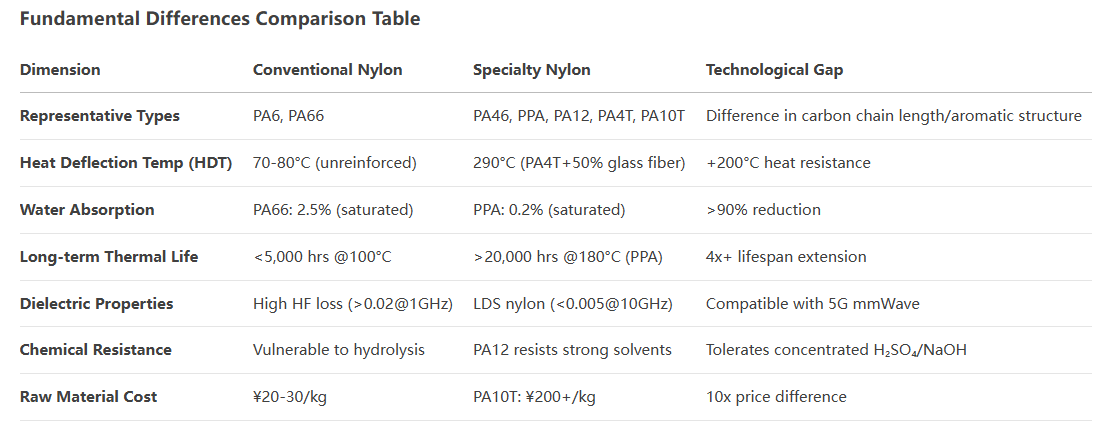

With the continuous advancement of polymerization technology, the application field of nylon has expanded from early ordinary decorative parts to load-bearing structural parts and functional parts. According to the chemical structure and performance characteristics, nylon can be mainly divided into two categories: traditional nylon and special nylon.

I. Molecular Structure Design

Conventional Nylon

Aliphatic long-chain structure (e.g., 6 carbons in PA6) → High flexibility but limited heat resistance

Pain point: High amide bond density → Water absorption >1.5% → Dimensional instability (PA66 swells 0.8% post-absorption)Specialty Nylon

① Semi-Aromatic TypePPA/PA4T/PA6T: Rigid benzene rings → ↑Heat resistance ↓Water absorption

② Long-Chain TypePA12/PA1214: ≥12 carbons → ↑Flexibility ↑Cryogenic resistance (no fracture @-40°C)

③ Copolymer-ModifiedPA6/66: Third monomer → Disrupts H-bond network → Lower crystallinity for better processability

II. Extreme Performance Breakthroughs

III. Manufacturing Process Evolution

Conventional Nylon: Melt polycondensation → Underwater pelletizing → Injection/extrusion molding

Limitation: Broad MW distribution (PDI>2.0) → ±15% performance variation

Specialty Nylon:

① Solid-State Post-Condensation: MW>50,000 → 3x↑ creep resistance

② Reactive Extrusion: In-situ nano-clay reinforcement → Flexural modulus: 12GPa

③ Stereocomplex Technology: L/D molecular pairing → M.p.↑ to 280°C (vs. 220°C for PA6)

IV. Cost-Performance Balance Strategy

Material Selection Golden Rules:

➊ Temp >120°C → Mandatory: Semi-aromatic nylon (PPA/PA4T)

➋ Humid environments → Prefer PA10T/PA6T (water abs. <0.8%)

➌ Dynamic load parts → Glass-filled PA66 (optimal cost-performance)

Conclusion

While conventional nylons (PA6/66) remain industrial staples, specialty nylons leverage precision molecular engineering to dominate extreme conditions (high temp/humidity, HF signals, corrosion). With bio-based and circular technologies converging, specialty nylons are transitioning from "high-performance premiums" to "sustainability essentials", heralding a new era for engineering plastics.