From basic properties of silicone oil to innovative applications

I. The Origins and Evolution of Silicone Oil

Silicone oil (polysiloxane) traces its roots to the 1940s, when breakthroughs in the direct synthesis of methyl chlorosilane enabled its industrial-scale production. Its unique **Si-O-Si backbone with organic side groups grants:

Exceptional thermal stability (-50°C to 300°C)

Ultra-low surface tension (21 mN/m, just 1/3 of water)

Physiological inertness (ISO 10993 biocompatibility certified)

Initially used in military and aerospace applications, silicone oil now permeates industries like healthcare, electronics, and personal care.

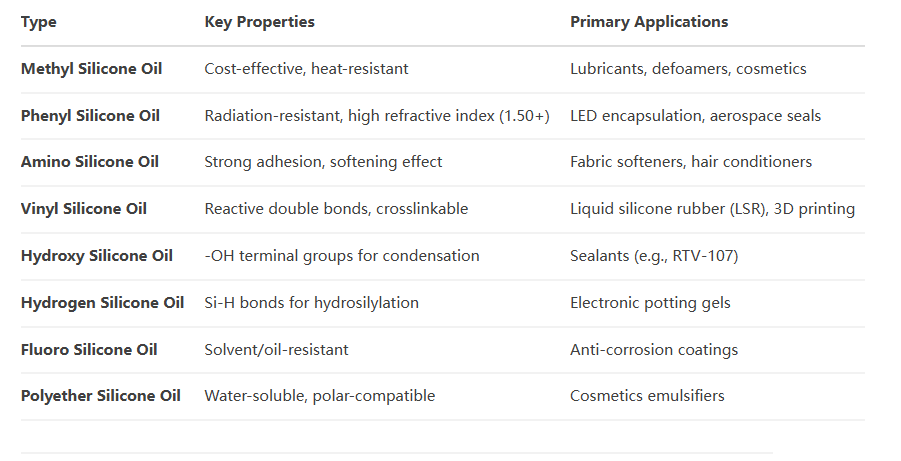

II. The Silicone Oil Family: 8 Key Variants

III. Why Is Silicone Oil Irreplaceable?

1. Thermal Resilience

- Decomposition temp >250°C (short-term 300°C for engine lubrication)

- Remains fluid at -50°C (ideal for polar equipment)

2. Triple-Shield Performance

- Waterproof**: Contact angle >100° (textile treatments)

- Non-stick**: 1/10 the release force of conventional oils

- Aging-resistant**: <5% degradation after 10 years outdoors

3. Safety & Compatibility

- Medical-grade oils for joint implants (20+ years in vivo)

- FDA-approved food-grade release agents (21 CFR §178.3570)

IV. Global Applications

1. Electronics

- Thermal pastes (5~8 W/m·K) for CPU cooling

- Dielectric gels in EV battery modules

2. Healthcare

- Retinal detachment surgery fillers

- Scar-reduction gels (60% less hypertrophy)

3. Green Energy

- Solar panel sealants (25-year UV resistance)

- Wind turbine blade hydrophobic coatings

4. Consumer Goods

- "Soft-focus" silicone elastomers in cosmetics

- Phthalate-free baby bottle nipples

V. Cutting-Edge Innovations

1. Smart-Response Silicones

- Thermothinning oils: Viscosity drops at 40°C for self-regulating lubrication

- UV-curable silicones: 10-second curing for electronics encapsulation

2. Sustainable Solutions

- Bio-based silicones (30% plant-derived, e.g., Clariant’s EcoTain)

- Biodegradable silicones (ester-modified, >90% degradation in 6 months)

3. Nano-Enhanced Formulations

- Graphene/silicone composites: 15 W/m·K thermal conductivity

- Aerogel-reinforced oils: Thermal insulation for spacecraft

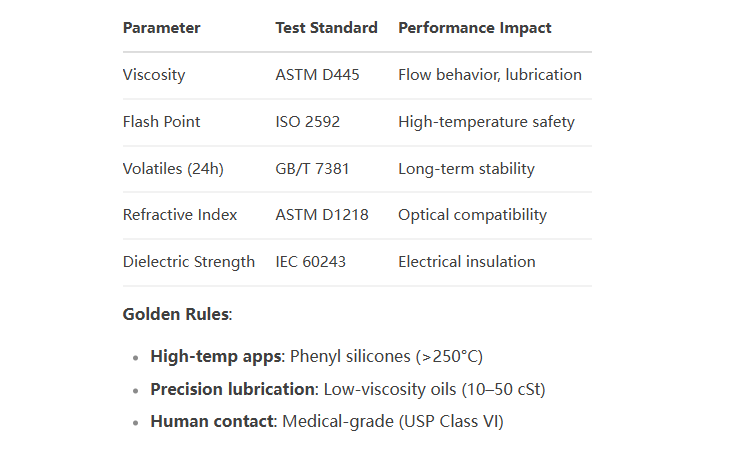

VI. Selection Guide: Critical Parameters

Golden Rules:

High-temp apps: Phenyl silicones (>250°C)

Precision lubrication: Low-viscosity oils (10–50 cSt)

Human contact: Medical-grade (USP Class VI)

VII. Global Market Insights

Market size: $12 billion (2023), growing at 5.8% CAGR (Grand View Research)

Key players:

USA: Dow, Momentive (high-end markets)

China: Hoshine, Wynca (60% global capacity)

Europe: Wacker (medical/electronic grades)

Conclusion

From industrial lubricants to medical implants, CPU thermal management to space exploration, silicone oil’s versatility continues to drive innovation. With advancements in green chemistry and nanotechnology, its potential is limitless.