Introduction to Common Nylon Materials

Nylon, as the first of the five major engineering plastics, is a long-chain polymer composed of repeating amide groups (-CO-NH-) with good mechanical properties, wear resistance, self-lubrication and chemical stability. According to the different molecular structures, the nylon family is divided into many types, each of which has its own unique properties and application areas.

1. Ordinary nylon

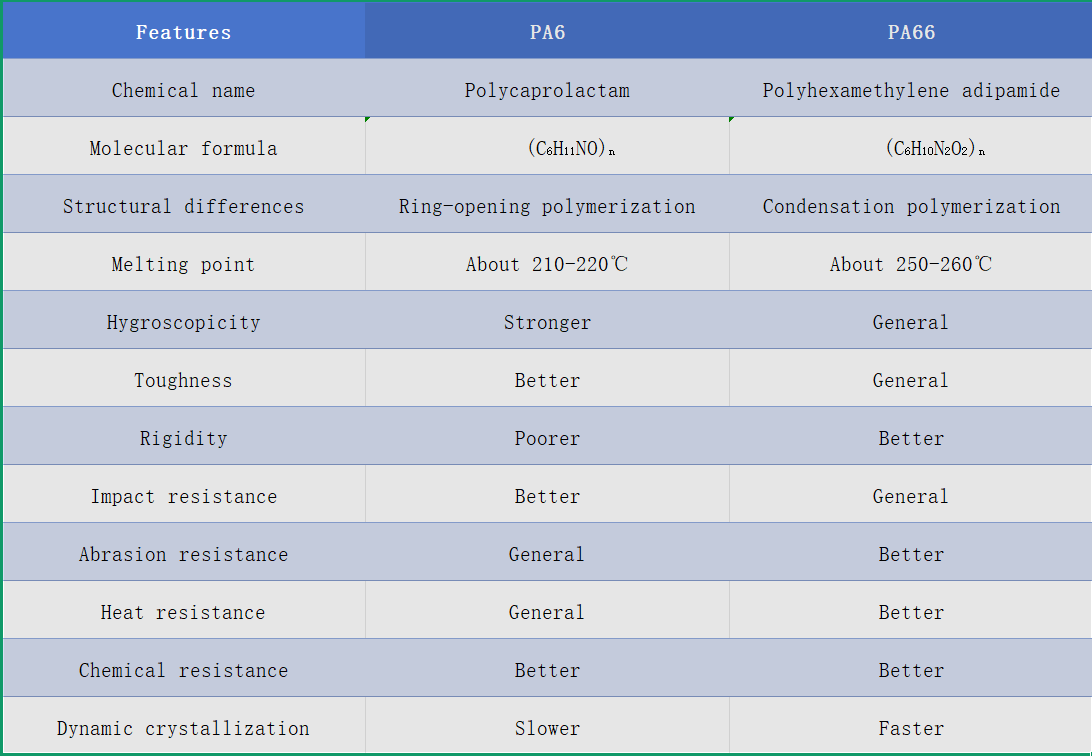

PA6 (polycaprolactam) and PA66 (polyhexamethylene adipamide)

These two brothers are the most common nylon materials, accounting for 90% of the nylon production scale, while the global nylon production capacity is only more than 10 million tons! PA6 exceeds 6 million tons, PA66 exceeds 3 million tons, PA6 is the cheapest nylon, followed by PA66!

PA6: Suitable for occasions requiring good toughness and diverse processing and molding, such as automotive parts (gears, bearings), electronic and electrical products (housings, connectors) and textiles (carpets, ropes).

PA66: Suitable for high strength, high rigidity, heat resistance, and wear resistance, such as the automotive industry (under-hood parts, brake system parts) and industrial machinery (gears, pulleys).

2. High temperature nylon (heat resistance > 250°C)

High temperature nylon is usually semi-aromatic nylon (containing benzene ring structure), with high melting point and low hygroscopicity, suitable for high temperature and high humidity environment. PA6T, PA9T, PA10T, PA4T and other PA+number+T are all high temperature nylons, and fiber reinforcement is as high as PA46. Even after some PA6T and 9T are modified, the heat deformation temperature reaches 290+, but the resin heat resistance is still the best PA46. In the PAXT series of high temperature nylon, it has excellent chemical resistance and high dimensional stability. Main applications: electronic components, connectors,

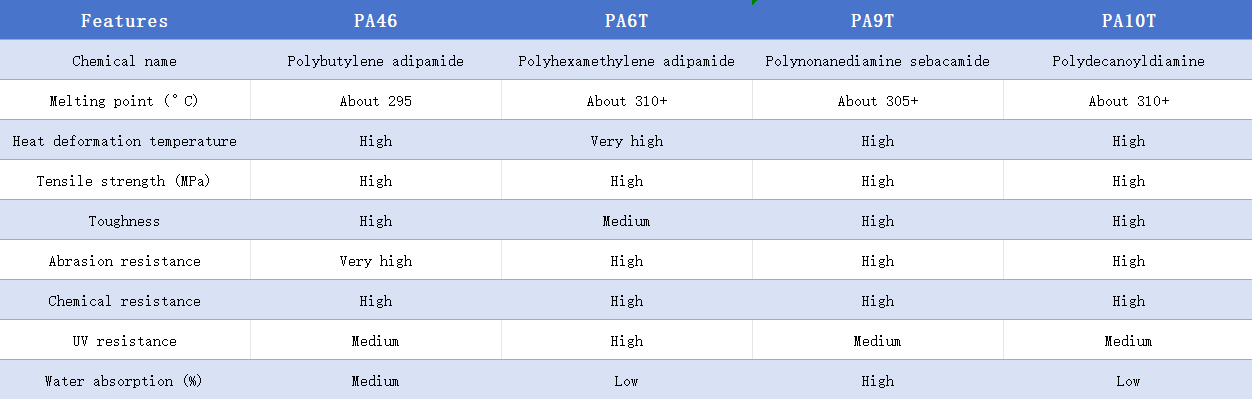

PA46 (polyamide 46, polybutylene adipamide):

Synthesized from adipic acid and butanediamine, with a melting point of about 290°C, it has excellent heat resistance and mechanical properties. It has low hygroscopicity and excellent dimensional stability, making it suitable for use in high temperature and humid environments. PA46 also has good chemical resistance and excellent impact resistance.

PA6T (polyhexamethylene terephthalamide)

Polyhexamethylene terephthalamide is a copolymer of PA6T and PA66, a heat-resistant nylon 6T/66. The melting point is as high as 310°C. The main characteristics are excellent high-temperature rigidity, dimensional stability and chemical resistance. The excellent properties make PA6T widely used in many fields including automotive parts, mechanical parts and electrical/electronic parts.

PA9T

PA9T is an original polyamide engineering plastic developed by Kuraray from raw material monomers. It is a molding material with excellent heat resistance, chemical resistance, and sliding resistance that can withstand repeated friction. It is often used in applications in high temperature environments, such as automobiles, electronics, aviation and other fields. The melting point of PA9T is 306℃, and it has a higher glass transition temperature (125℃) and crystallinity than other nylons, which enables it to maintain good toughness at high temperatures.

PA10T (polydecane terephthalamide)

PA10T is made of terephthalic acid and decanediamine as monomers through polycondensation. It has excellent heat resistance, a melting point of 316℃, chemical corrosion resistance, low water absorption, good dimensional stability, and after glass fiber reinforcement modification, it can withstand lead-free solder temperatures exceeding 280℃, and has excellent comprehensive performance.

PA4T (polytetramethylene ... PA12 (polylaurolactam)

Prepared by linearization of butadiene, petrochemical-based materials, high transparency, memory nylon is PA12, eyeglass frame resin material, melting point between 175°C and 185°C, but the improved PA12 is close to PA11 in thermal performance, resistant to low-temperature impact, good chemical resistance and oil resistance, low moisture absorption, excellent dimensional stability, and the lowest shrinkage rate among nylons. Applications: fuel systems, hydraulic systems, electronic components, glasses, etc.

3. Low temperature nylon, high tenacity nylon

PA610 (polyhexamethylenediamine sebacamide)

PA610 monofilament has excellent mechanical properties, impact resistance, wear resistance, impact resistance and low temperature performance, and good chemical stability. The performance of PA610 monofilament is between PA612 monofilament and PA66 monofilament, but its water absorption is small, it is resistant to strong alkali, and it is more resistant to weak acid than PA6 monofilament and PA66 monofilament. It is often used in nylon filaments for brushes.

PA612 (polyhexamethylene dodecanamide)

PA612 is also called polyamide 612 or nylon 612, and its composition is polyhexamethylene dodecanamide. In addition to the general characteristics of PA, PA612 also has the advantages of relatively small width, lower water absorption and density, good dimensional stability, high tensile strength and impact strength, and transparency. It is mainly used to make high-grade toothbrushes and other industrial bristles, and can also be used for oil pipelines, oil-resistant ropes, conveyor belts, bearings, gaskets and other electronic components.

4. Other nylons

PA1010 (nylon 1010)

It was developed in China in 1958. It is made by extracting decanediamine and sebacic acid from castor oil as raw materials and then condensing them. Its two main monomers are both from castor beans, and it is a renewable bio-based nylon material.

Its biggest feature is that it has high ductility and can be stretched to 3 to 4 times its original length. It also has high tensile strength, excellent impact resistance and low temperature resistance, is not brittle at -60°C, and has wear resistance, ultra-high toughness and good oil resistance. It is widely used in aerospace, cables, optical cables, metal or cable surface coating, etc.

PA1212 (Nylon 1212)

PA1212 resin has unique advantages. It has the lowest water absorption rate among nylons, good dimensional stability, oil resistance, alkali resistance and non-toxicity, chemical resistance, excellent wear resistance, good transparency, and excellent toughness at low temperatures. It is mainly used as a modified substrate and can be widely used in aerospace, automobile, textile, instrumentation, electrical, medical equipment and other industrial fields.

PA56 (Polyamide 56)

It is a new type of bio-based nylon. The PA11 mentioned above is also a bio-based nylon. PA56 is polymerized from bio-based pentamethylenediamine and petroleum-based adipic acid. The melting point is about 260℃, and its strength, softness, hygroscopicity, resilience and low temperature resistance are close to those of PA66.

MXD6 nylon

is a high barrier aromatic transparent nylon, the full name of which is poly(trimethylhexamethylene terephthalamide), which is a crystalline semi-aromatic polyamide. Nylon MXD6 has very outstanding gas barrier properties, and its comprehensive physical properties are better than PA66 and close to PPA, with good heat resistance and dimensional stability. The temperature resistance is slightly lower than that of the PPA system, and it has high strength and rigidity. This is the barrier nylon, MXD6 has good barrier properties, heat resistance and mechanical strength! MXD6 nylon stands out in packaging and automotive applications for its excellent gas barrier properties. It is well used in many high temperature products that require hydrolysis resistance and gas barrier resistance.

PA nylon elastomer

Also known as Thermoplastic Polyamide Elastomers (TPAE), it is a block copolymer modified on the basis of nylon such as PA11 and PA12, consisting of polyamide hard segments and aliphatic polyester or polyether soft segments. This material combines the strength of nylon with the flexibility of elastomers. It can be understood that the performance is a combination of PA11/12+TPU, showing a series of excellent properties from high tensile strength, low temperature resistance, elastic recovery, wear resistance and chemical resistance.

The unique properties of each PA make it irreplaceable in specific fields, and the selection needs to weigh heat resistance, hygroscopicity, environmental protection requirements and costs. From PA6, PA66 to PA11, PA12 and other polyamide series, each material has its own unique properties and applicable fields. With the advancement of science and technology and the enhancement of environmental awareness, the application of bio-based nylon such as PA11 and PA1010 has been increasingly valued, showing the potential for sustainable development.

In the future, polyamide materials will continue to play an important role in the fields of automobiles, electronics, packaging, textiles, etc., and promote the innovation and development of the industry. Whether it is high-performance engineering plastics or flexible and environmentally friendly materials, polyamide will become a key material to meet modern needs.