Exploring the Mysteries of Deep Processing of Organosilicon Products (Part Ⅲ)

Cited from:https://pixabay.com/

Deep processing of organic silicon refers to the further processing and treatment of organic silicon raw materials. Deep processing of organic silicon can make the organic silicon material better adapt to various application needs, improve the performance and function of the material, and expand its application fields. Today we’ll take a look at one of the earliest types of silicone materials—silicone resin.

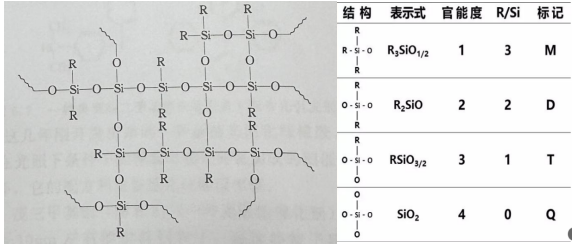

The structural main body of silicone oil and silicone rubber is a polydialkylsiloxane chain composed of difunctional siloxane, while silicone resin (siliconeresin) contains difunctional, trifunctional and tetrafunctional silica structural units. A highly cross-linked thermosetting polymer with the following structure:

R may be an organic group such as a methyl group or a phenyl group, or an active group remaining due to incomplete condensation such as a hydroxyl group or an alkoxy group.

Silicone resin is an earlier type of silicone material. However, compared with silicone oil and silicone rubber, silicone resin has fewer varieties and a smaller market share. Silicone resin is an organic prepolymer of polymethyl (phenyl) siloxane with Si-O-Si as the main chain, organic groups connected to the silicon atoms, and terminal groups with hydroxyl or vinyl groups. It is heated or in the presence of a catalyst It further condenses into a solid resin with a three-dimensional network structure that neither dissolves nor melts.

Classification of silicone resin

Named according to organic groups:

Methyl silicone resin, phenyl silicone resin, methylphenyl silicone resin, etc.

Named by structural unit:

MQ, MTQ, TQ, MDQ, etc.

Named according to purpose and form:

Varnish, insulating paint, coatings, adhesives, silicone molding compounds, resin powder, etc.

Named according to organic modified resin:

Silicone modified silicone resin, silicone modified polyester resin, silicone modified acrylic resin, silicone modified epoxy resin, silicone modified phenolic resin, silicone modified polyimide resin, etc.

Named according to curing cross-linking reaction:

Condensation silicone, addition silicone, peroxide initiated silicone. Among the three types of silicone resin, the condensation silicone resin uses the largest amount.

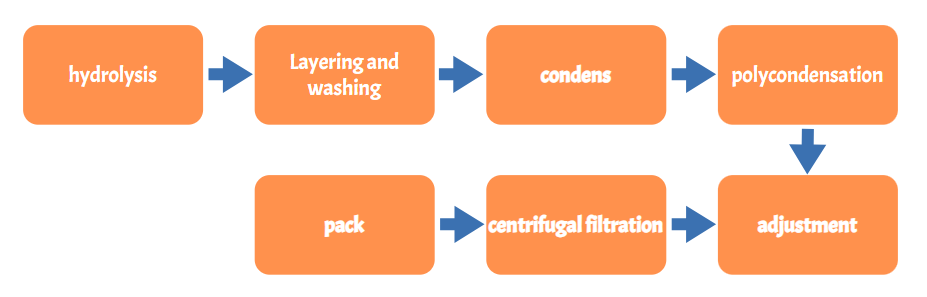

Silicone resin production process:

Production process raw materials: methyltrichloro(alkoxy)silane, dimethyldichloro(alkoxy)silane, methylphenyldichloro(alkoxy) stone sealant, phenyltrichloro(alkoxy) ) silane, diphenyldichloro(alkoxy)silane, silicon tetrachloride and corresponding alkoxysilane, etc.

Catalyst: naphthenate or carboxylate of Pb, Zn, Sn, Co, Fe, Ce, etc., perfluorosulfonate, chlorinated phosphazene [such as (PNC12)], amines, quaternary ammonium base, quaternary phosphorus Alkali, titanate esters and guanidine compounds, etc.

Solvent: alcohols such as butanol and isopropanol, toluene, xylene, etc.

Advantages and Disadvantages of Silicone

Advantages: Excellent high and low temperature resistance, weather aging and chemical corrosion resistance, excellent electrical insulation properties, low surface tension, and hydrophobicity.

Disadvantages: small intermolecular attraction, weak general mechanical strength (bending, tensile strength, impact, friction resistance, etc.);

Poor resistance to various organic solvents;

Poor adhesion to substrates such as metal and plastic;

Limited compatibility with other organic resins;

Main uses

Silicone resin is an important chemical product with a wide range of uses in industry. In addition to silicone insulating paint, silicone coatings, silicone adhesives and silicone molding compounds, it is also used to make silicone rubber, silicone oil, silicone resin composite materials, etc. In the construction industry, silicone resin is also commonly used in waterproofing materials, sealing materials, etc. In addition, silicone resin is also widely used in electronics, automobiles, aerospace and other fields, playing an important role.

In general, the deep processing of silicone products is to further process the raw materials to improve their performance and functions, thereby expanding their application areas. Silicone rubber, silicone oil and silicone resin are the three pillar products in the silicone industry. Although silicone resin has a small market share, it has an irreplaceable position in many fields. As a kind of silicone material, silicone resin has excellent high and low temperature resistance, chemical stability and electrical insulation properties, and plays an important role in many fields. Through different classifications and production processes, silicone resin can be used in insulating paint, coatings, adhesives, molding materials, etc. to meet the needs of different industries. The wide application of silicone resin provides high-performance material options for various industries and promotes the development and progress of industrial technology.