The application of silicone foam material in electric vehicle

With the rapid rise of the global new energy vehicle market, electric vehicles (EVs) have become the mainstream choice for future transportation, with lithium batteries as the core power source. The safety of lithium batteries has always been a focal point of the industry. In order to prevent safety incidents such as short circuits, overheating, and even fires during battery operation, various safety technologies have emerged. Among these, silicone foam materials, with their unique flame-retardant properties and excellent thermal insulation performance, play an increasingly important role in the Battery Management System (BMS) and battery module design.

This article will provide a detailed introduction to the application of silicone foam materials in lithium battery safety and their crucial role in the new energy vehicle industry. It covers the industry background, types of flame-retardant materials, the advantages and disadvantages of different materials, and the applications of silicone foam materials.

Industry Background of Silicone Foam Materials

In recent years, the rapid development of new energy vehicles has driven the expansion of the lithium battery industry, highlighting the growing safety concerns. Especially in high-voltage battery packs for electric vehicles, the risk of battery fires or explosions has greatly increased due to the high temperatures generated during battery operation or potential external impacts. Therefore, the fireproofing, thermal insulation, and thermal management systems of battery packs have become critical considerations for manufacturers during battery design.

Silicone foam materials, with their light weight, thermal insulation, and flame-retardant properties, have quickly found their place in the field of battery safety. As a high-performance material, silicone foam materials not only effectively protect battery packs from high temperatures but also reduce the risk of thermal runaway caused by external impacts, ensuring the safety of electric vehicles.

Classification of Flame-Retardant Materials

Currently, commonly used thermal insulation materials for power batteries include foamed plastics, plastic foams, ultra-fine glass wool, high-silica cotton, vacuum insulation boards, and silica aerogels. The thermal insulation boards inside the battery pack are placed between individual battery cells to effectively delay or block the spread of thermal runaway from a single cell to the entire battery system. Flame-retardant materials are designed to slow down or prevent the spread of fire and are widely used in electronics, appliances, construction, and automotive industries. Depending on the usage requirements, flame-retardant materials can be roughly classified into the following categories:

1. Inorganic Flame-Retardant Materials: Examples include aluminum oxide, aluminum hydroxide, etc. These materials have good flame-retardant properties but are typically brittle and have high processing costs.

2. Organic Flame-Retardant Materials: These include materials containing chlorine, phosphorus, or nitrogen compounds, which offer good flame-retardant properties but may pose risks to the environment and human health.

3. Silicone Flame-Retardant Materials: Silicone materials have natural advantages in flame retardancy and are often used in high-end products. Their benefits include excellent heat resistance, non-toxicity, odorlessness, and no environmental pollution.

Advantages and Disadvantages of Silicone Foam Materials

Advantages:

1. Excellent Flame-Retardant Properties: Silicone foam materials have strong flame-retardant properties. Not only can they withstand high temperatures, but they can also effectively prevent the spread of fire. This is due to the unique molecular structure of silicone, which allows it to resist decomposition at high temperatures and protect the battery from fire hazards.

2. Good Thermal Insulation: Silicone foam materials have excellent thermal insulation performance, which can effectively suppress excessive battery temperatures and reduce the risk of thermal runaway.

3. Environmental and Safety Friendly: Unlike some traditional flame-retardant materials that contain chlorine or phosphorus, silicone materials are non-toxic, odorless, and free from harmful substances, meeting the high standards for environmental and safety requirements.

4. Impact Resistance: The elasticity and flexibility of silicone foam materials allow them to absorb external impacts effectively, reducing the likelihood of battery damage.

Disadvantages:

1. High Cost: The production cost of silicone foam materials is relatively high, which limits their application in low-end markets.

2. Durability Issues: Although silicone materials are heat-resistant, they may age or harden in extreme environments, which requires careful consideration of their long-term durability in product design.

Applications of Silicone Foam Materials

1. Battery Management System (BMS)

The Battery Management System (BMS) is the "brain" of the electric vehicle's battery pack, responsible for monitoring parameters such as charging, discharging, voltage, and temperature. Silicone foam materials can be used in the BMS system for thermal management and insulation, playing a role in flame retardancy, heat protection, and shock absorption, thus ensuring the safety of the battery in extreme operating environments.

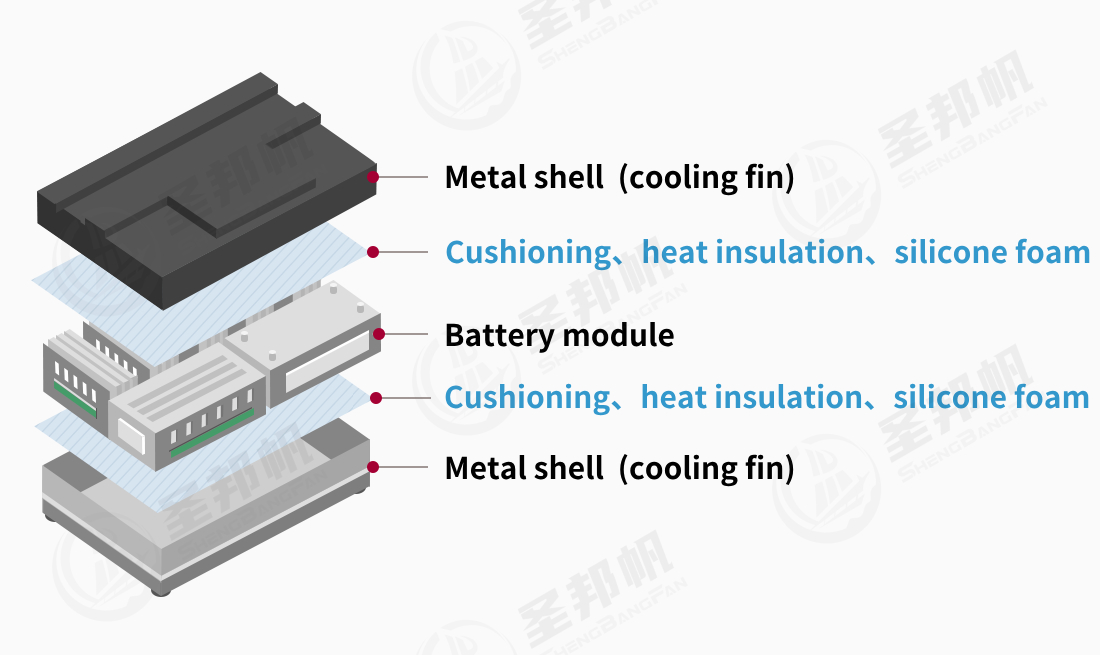

2. Battery Modules and Packs

The internal structure of a lithium battery pack is complex, and measures for thermal insulation, cushioning, and fire protection between individual battery cells are crucial. Silicone foam materials can effectively fill the gaps between cells, providing excellent thermal isolation and protection. Especially under high-temperature or high-pressure operating conditions, the flame-retardant properties of silicone foam materials can effectively prevent thermal runaway, ensuring battery safety.

3. External Insulation Materials for Electric Vehicles

In addition to applications within battery packs, silicone foam materials are widely used for insulation in electric vehicle bodies, windows, and electric drive systems. Especially during high-speed driving, electric motors, electronic components, and battery systems generate significant heat. Silicone foam materials can provide excellent thermal protection.

4. Other High-Temperature Environment Applications

Apart from new energy vehicles, silicone foam materials are also widely used in aerospace, industrial equipment, home appliances, and other industries. Their excellent thermal insulation and flame-retardant properties make them suitable for use in high-temperature, high-pressure, and flammable environments.

Conclusion

With the rapid development of the new energy vehicle industry, the safety of lithium batteries has become increasingly important. Silicone foam materials, with their excellent flame-retardant, thermal insulation, and environmentally friendly properties, have become an important material in ensuring battery safety, especially in electric vehicles. With ongoing technological advancements and a gradual reduction in costs, the application of silicone foam materials in the new energy vehicle industry will continue to expand, providing more reliable protection for battery safety.

Through in-depth research on silicone foam materials, we can foresee that, with the growing global demand for electric vehicle safety and environmental standards, silicone foam materials will continue to play a unique role in supporting the sustainable development of the new energy vehicle industry.