The Four Types of Silicone rubberand Their Differences: A Comprehensive Guide

The Four Types of Silicone rubberand Their Differences: A Comprehensive Guide

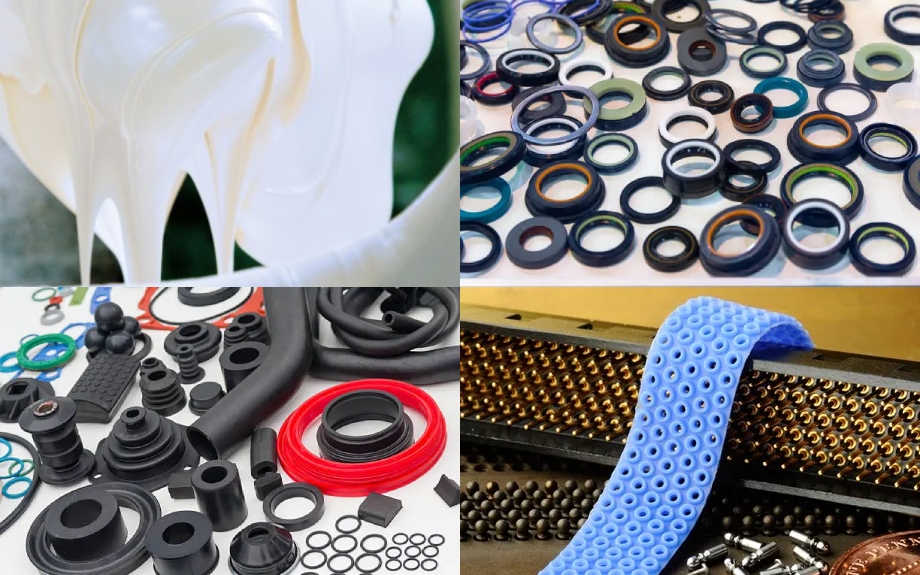

Silicone rubber, a versatile material with numerous applications, comes in various types, each possessing unique characteristics and uses. Silicone rubber can be divided into liquid silicone rubber (LSR), high consistency silicone rubber (HCR), room temperature vulcanization (RTV) silicone, fluorine silicone four types.

The main differences between these silicone rubber types are their molding process, hardness range, usage characteristics and processing methods. Each type of silicone rubber has specific characteristics and scope of application to meet the needs of different industries and application areas.

1. Liquid silicone rubber (LSR) :

Liquid silicone rubber, commonly known as LSR, is a two-component platinum-cured elastomer composed of silicone polymers, commonly used in injection molding and suitable for manufacturing products such as precision parts, seals and medical devices.

2. High consistency silicone rubber (HCR) :

High consistency silicone rubber, also known as HCR, is a non-flowing silicone rubber, after heat curing to reach the final shape, usually through extrusion, calendering or compression molding process processing, suitable for the manufacture of sealing rings, pipes, insulation and other products, with excellent wear and aging resistance.

3. Room temperature vulcanization (RTV) silica gel:

Room temperature vulcanized silica gel, commonly known as RTV silica gel, is a single component silicone rubber, curing at room temperature through wet gas curing process, widely used in mold making, sealant, electronic poiling and other fields, with good fluidity and adhesion, and can be cured without heating.

4. fluorosilicone:

fluorosilicone is a special kind of silicone rubber, usually has the structure of fluoride and silicon. It has excellent high temperature resistance, chemical corrosion resistance and electrical insulation properties. It is commonly used for special applications such as high temperature resistance, chemical corrosion resistance and electrical insulation, such as aerospace, semiconductor manufacturing and chemical industries.

Conclusion:

In conclusion, knowing the different types of silicone available-Liquid Silicone Rubber (LSR), High Consistency Silicone Rubber (HCR), Room temperature vulcanization (RTV) silica gel, and fluorosilicone-is crucial for making informed decisions in various industries. By understanding their differences in composition, curing processes, and applications, professionals can choose the most suitable silicone type for their specific needs. So, whether you're looking for a flexible and moldable material or a compressible foam, the world of silicone has you covered.