Silicone Oil in Sewing Thread

Release Time: 2023-01-05 11:05:24

Silicone Oil in Sewing Thread

Photo Cover cited from: https://pixabay.com/photos/yarn-thread-sew-thread-spool-1615524/

As introduced in the last blog, many types of dimethyl silicone oil are applied in different aspects of fabric & textile industry. They could be used as lubricants, finishing agents, blocking agents, additives and many other textile chemicals. Today this article is going further to one of the main applications of silicone oil in textile industry- the dimethyl silicone oil in the sewing thread processes.

The general characteristics of sewing thread silicone oil are a small viscosity-temperature coefficient, a low surface tension, high lubricity, strong adhesion and high reservation. The price is relatively low, useful and economic. The product usually exists in the form of transparent liquid. The viscosity of it is between 300~1000 CST when the temperature is 25 Celsius Degrees and the percentage is 99%.

The sewing thread silicone oil is applied in almost all types of sewing threads. During the sewing thread processes, the silicone oil is mainly being used as lubricants and it is applied in one of the most important manufacturing processes of different fabrics or textiles. In China, the working efficiency of sewing thread machine is 5000 stiches per minute while in some other nations the number could increase to 7000 ~ 8000 stiches per minute. These mean the stiches of sewing thread machine would be very high which may lead to the breaking of the sewing threads. It is due to the long-time running of the stiches under this kind of situation, thus the sewing thread must have some extra protections which may grant it high heating resistance, high isolation and high lubricity.

The Introduction to Sewing Thread Machine

It is to give the readers a better impression, a brief introduction to the corresponding process machine is necessary.

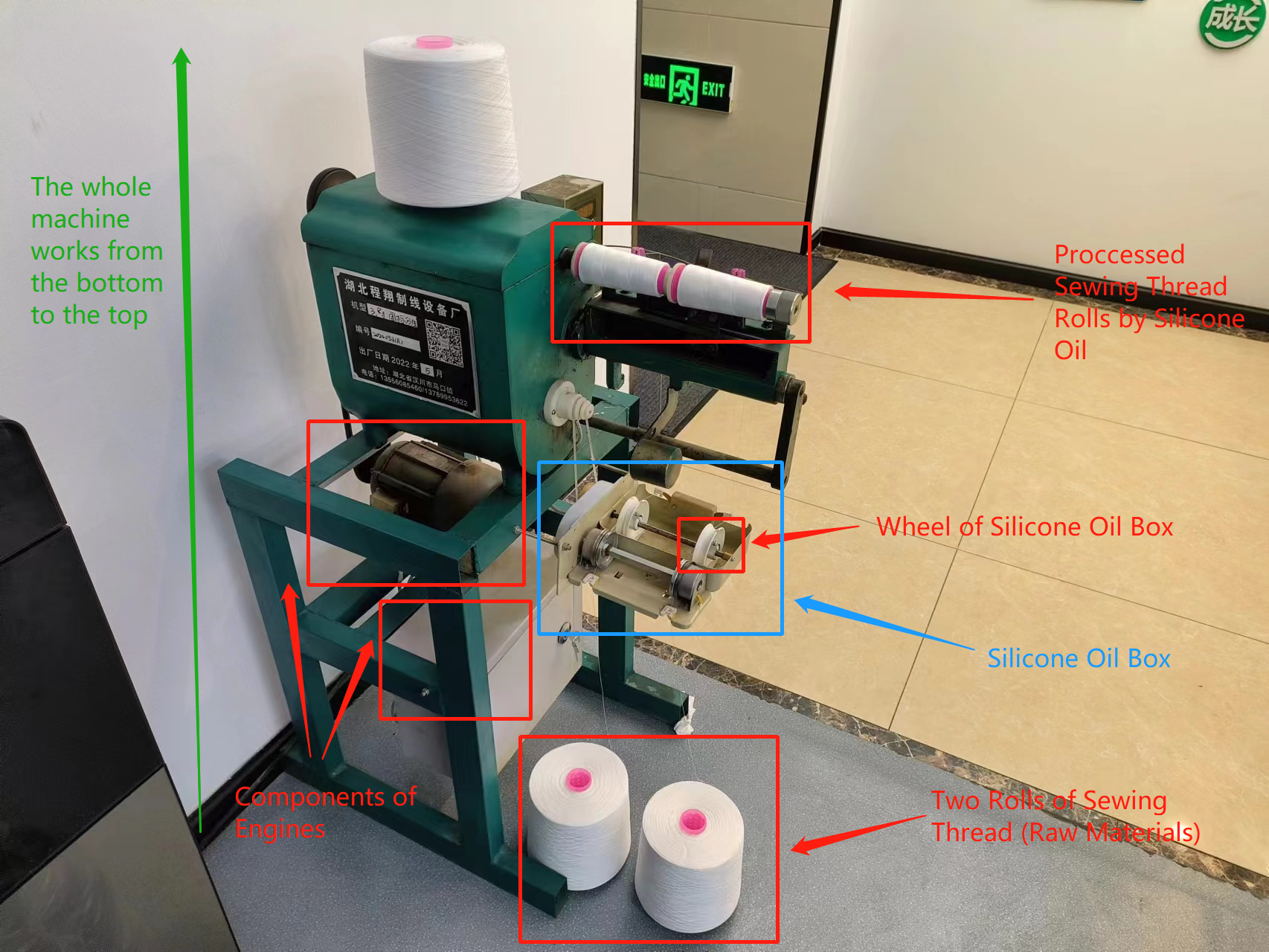

A typical type of sewing thread processing machine is like this (as showing in the picture below):

Some of the machine parts are noted in the picture above. As it shows, the power supplying components are put at the bottom of the machine to avoid interrupting the processing of the threads at the top. The raw materials which are the sewing threads in the form of rolls are displayed on the ground. The sewing thread will be passed throughout the whole machine from its bottom to the top by the automatically moving of the belts. In the middle of the transportation, there will be two side rolls shown in the right top of the photo, the thread will all be passed through these two rolls and the box which place the silicone oil located just below the two rolls. This ensures every side and part of the sewing thread will go through the silicone oil placed in the box to get the extra protection. If you want to know more about the machine's working, you could see the video we provided on youtube here.

The whole performance process will be shown in the meter sign board with red digital numbers. Basically the processed thread will not have changes on its appearance since the silicone oil is transparent and will not influence the colors of the sewing threads.

The Detailed Applications of Silicone Oil

There are usually two ways of silicone oil processing on the sewing threads. The first is the immersion, the second is the contact. If the immersion method is applied, cation hydroxy silicone oil emulsion or silicone wax water lotion will be applied; if the contact is applied, the materials will usually be wire silicone oil, dimethyl silicone oil or silicone wax lotion. The effectiveness is from low to high. The common two ones are the silicone oil emulsion and dimethyl silicone oil due to the high effectiveness and affordable prices.

From the theory, the silicone oil could be sustained on the surface of sewing threads for a longer time. The structure of sewing thread is fluffy. By adding silicone oil into the sewing threads, the oil could enter the inside of the threads and then lead to the toughness and the pulling strength of the inside of sewing threads to be stronger. The main goal of adding silicone oil to the thread is to increase the sewing thread’s lubricity, electrical isolation and some other features. These goals are surely achieved. To be more specific, the new lubricity could lead the sewing thread to be processed by 7000 ~ 8000 stiches per minute; the good electrical isolation could increase the collection of sewing thread and avoid them from further separation; the difference between dynamic friction and static friction will also be smaller which allow the shakes occurred in the manufacturing process will be fewer, and the final clothes will be more clean and smooth; This could also avoid the sewing thread from being broken or burnt which may cause lots of loss during manufacturing processes; the corresponding glossy will also be improved which will make the finally manufactured clothes to be nicer.

As for the consuming amount for silicone oil for this, the average consuming ratio is usually 1:50. To be more specific, for each 1 ton of sewing thread, they only need 50kg of silicone oil to be lubricated. This means the cost of silicone oil on this subject is relatively and reasonably low and affordable to most fabric & textile manufacturers.

The price of silicone oil is also affordable to compare with other similar chemicals, it is due to the large amount of silicon elements exist on the earth and the manufacturing of silicone oil cannot be regarded as difficult ones. The silicone oil is also more recyclable and environmentally friendlier than many other chemicals.