Silicon Wafer: Silicon-Made Core Product

Release Time: 2022-11-24 10:27:57

Silicon Wafer: Silicon-Made Core Product

Cited from: https://pixabay.com/photos/cpu-chip-semiconductor-condenser-3061923/

Cover Photo cited from: https://pixabay.com/illustrations/circuit-board-circuit-control-center-410099/

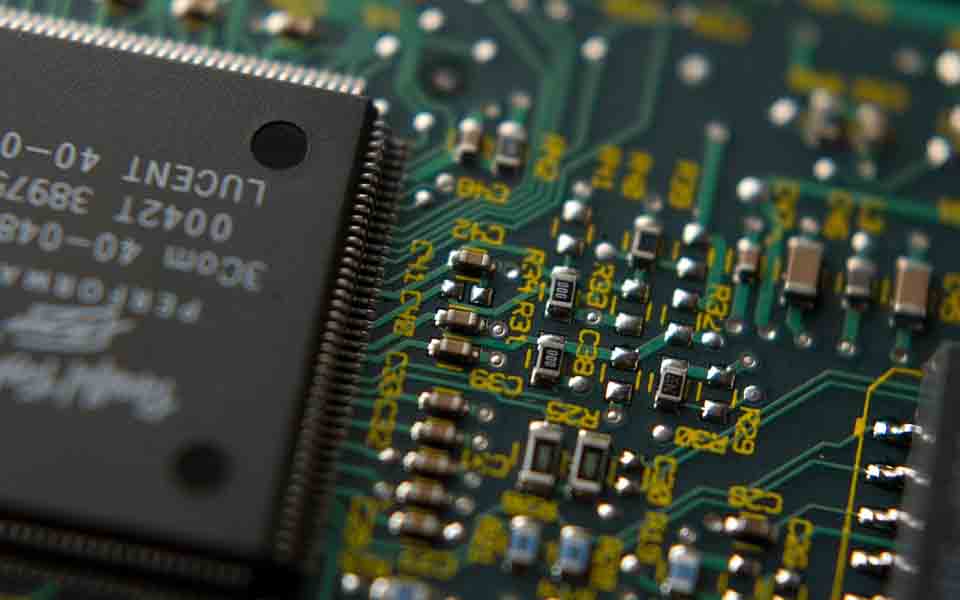

In today’s electronics, silicon wafers are thin slices of high-purity crystalline silicon (c-Si) used to produce integrated circuits—a composite material made up of multiple electronic components. It is also known as a substrate or wafer. Silicon wafers serve as substrates for microelectronic devices and are particularly useful in building electronic circuits due to their electrical conductivity and affordability.

Although silicon crystals may look metallic, they're not quite metal. Because of the "free electrons" that move easily between atoms, metals are good conductors of electricity, which is the movement of electrons. Pure silicon crystals, on the other hand, are almost insulators. Allows very little current to pass through it. However, this can be changed through a process called doping.

Doping is the mixing of small amounts of impurities into the silicon crystal to change its behavior and integrate it into the conductor. These impurities used for doping are called dopants. Silicon itself does not conduct electricity very well, however it can be used with dopants to precisely control the resistivity to a precise specification. Silicon dopants such as nitrogen, indium, aluminum, gallium and boron can be added throughout the growth process. Therefore, to form a semiconductor from non-conducting silicon, the silicon must be turned into a wafer.

So, silicon wafers, depending on the doping level. Semiconductors can be considered intrinsic or extrinsic. When it involves light or moderate doping, it is extrinsic and when it involves high concentration doping, it is considered intrinsic.

Silicon wafers come in many shapes and sizes, mostly depending on what they are used for. They are key components in integrated circuits, which are made up of several electronic components designed to perform specific tasks. Silicon, a flat disk with a polished, mirror-like surface, is ubiquitous and found in nearly all electronic devices. Because of its smooth surface and improved purity, it is suitable for semiconductor devices.

A well-known silicon wafer fabrication method is the vertical Bridgman and Czochralski method. In addition, float zone methods are becoming more popular recently due to their low defect count and high purity, and they are widely used in the manufacturing processes of chips and microchips for electronic equipment.

Application of Silicon Wafer

As mentioned above, the primary use of silicon wafers is in integrated circuits (ICs), as it forms the key components of ICs. An IC is a collection of electronic components that work together to perform a specific task. Although different semiconductors have been tested over time, silicon has proven to be a more stable choice. Silicon chips are used in all kinds of gadgets all over the world. Its application spans different types of industries. The following are some applications of silicon wafers:

1. Semiconductor.

Semiconductors come in different forms and shapes and are an integral part of a variety of electronic devices. These include transistors, diodes and integrated circuits. They are manufactured using silicon wafers, which contribute to their compactness and efficiency. Because of their ability to handle a wide range of voltages or currents, they are used in optical sensors, power devices and even lasers.

2. Electronics and Computing

Silicon wafers are widely used in electronics and computing, thus driving the development of the digital age. A RAM chip is an integrated circuit, made from silicon wafers. This has given silicon wafers an important place in the computing industry. Additionally, silicon wafers are commonly used to manufacture many devices such as smartphones, automotive electronics, home appliances, and drone technology. Virtually any electronic circuit device has advanced use cases for silicon wafers, and new manufacturing techniques and automated processes are making them more effective and efficient.

3. Optics.

For optical grading, polished silicon wafers are usually purpose-built. Silicon wafers are the perfect economical material for reflective optics and infrared (IR) applications. The floating zone or CZ fabrication method is used to fabricate silicon wafers for optics. This is because these methods produce fewer defects and are higher than other methods. Used worldwide in micro-optics and fiber optic devices. An obvious example is the image sensor (CIS) made of complementary metal-oxide semiconductor (CMOS) used in cameras.

4. Solar cells.

Solar cells need silicon wafers to be more efficient and absorb more sunlight. Materials such as amorphous silicon, single crystal silicon, and cadmium telluride are often used. Manufacturing processes, such as the floating zone method, can increase solar cell efficiency by nearly 25 percent. Just like microchips, solar cells follow a similar manufacturing process. The level of purity and quality required for solar cells is not as demanding as for computing and other electronics.

5. Aerospace.

Due to its superior performance and quality, silicon wafers have been used in the aviation field since their birth. Silicon wafers are frequently used in the aerospace industry as covering and bonding materials, and to protect precision tools from extreme temperatures. It has been a good and trusted choice for decades due to its widespread use and resistance to high temperatures. Silicone is the most commonly used material in this industry. Chemically bonded polymers formed on long-chain oxygen, along with silicon components, make up most of this. Silicon wafers are useful in aircraft original equipment manufacturing (OEM) as well as in repair, maintenance and overhaul.

The difference between silicon wafer and chip

An integrated circuit is called a chip, which is a small electronic device that is a package of circuits, pathways, and transistors, etc., all of which work together to perform a specific task or possibly a series of tasks. These chips are the backbone of most modern electronics, including microprocessors, audio and video equipment, and cars. Integrated circuits are embedded in chips. Chips contain electronic components such as transistors.

A silicon wafer is a thin slice of semiconductor material that is used in the manufacture of integrated circuits. It's like a base on which integrated circuits can be formed. These flakes are considered the heart of electronics. Microcircuits on wafers are formed by the diffusion and deposition of various substances. The ever-evolving electronics industry has always tended to form thinner chips that are more efficient and less expensive than previous versions.

So, the main difference between a wafer and a chip is that the wafer acts as the base of the chip or the chip is embedded in the wafer, and together they form an important unit that is widely used in the field of electronics.

Summary

Silicon wafers are used in almost every element of human life and technological advancement, due to its stability compared to other semiconductor materials, silicon wafers are the most widely used material in the field of technology.